Modern garage systems combine strength, balance, and automation to deliver lasting performance. Yet, even minor wear can disrupt motion and weaken supporting structures. Skilled technicians examine every component before applying precision adjustments for dependable outcomes. With complete attention to detail, Garage Door Repairs become a reliable solution that restores both safety and function.

Restoring Strength Through Professional Service

A full-service approach starts with understanding how mechanical tension affects the overall door frame. Specialists inspect springs, rollers, and tracks before beginning any restoration. Each repair aims to extend operational life while reducing friction-related strain on moving parts.

Operational Faults Needing Technical Precision

Technicians often find several hidden issues once the door’s movement is fully tested. Slight misalignment or cable slack can quickly lead to irregular motion. Restorative techniques use calibrated tools to bring every part back into sync.

- Reinforces frame without excess material pressure

- Reduces motor effort for automatic systems

- Balances spring tension across door panels

- Improves alignment through guided adjustments

When completed, movement feels effortless and noise levels reduce significantly. Skilled teams ensure the system functions evenly, preventing future imbalance or jerky motion.

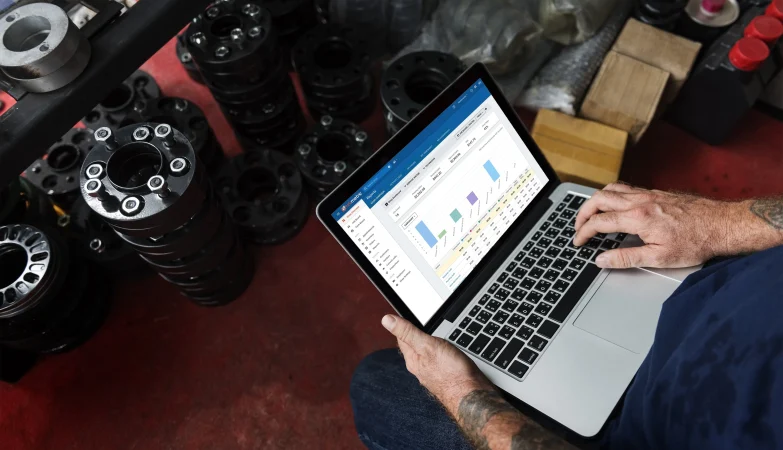

Performance Checks Ensuring Smooth Functionality

Routine testing helps verify that structural load remains distributed evenly. Each cycle exposes how resistance affects cables and hinges. During this stage, Garage Door Repairs focus on tension calibration to ensure long-term stability. A properly serviced mechanism protects the motor from premature failure while maintaining consistent speed and lift across every use.

Why Do Doors Lose Balance?

Sometimes homeowners notice one side lifting faster than the other. This imbalance may result from uneven cable tension or a weakened spring. Over time, that misalignment can place strain on joints, causing grinding or sticking during closure. Early inspection prevents those mechanical stresses from spreading into connected parts.

Can Small Cracks Affect Stability?

Tiny fractures in metal panels or brackets might seem harmless. Yet repeated vibration during opening gradually deepens those marks. Technicians often reinforce vulnerable zones before damage spreads to surrounding joints. Addressing such concerns early saves both cost and effort later.

Lasting Repairs Reinforcing Structural Integrity

Specialized tools are used to test joint resistance under various loads. Once precise readings are achieved, the reinforced hardware is resecured with durable fasteners. Regular lubrication of hinges and bearings maintains that balance, allowing smoother performance even under heavier daily use.

Consistent Function Backed By Expertise

Reliable operation depends on both skill and attention to detail. Comprehensive service restores confidence while preventing sudden breakdowns or uneven lifting. Professional inspections ensure continued safety, quiet performance, and durable functionality across changing conditions.